Benchtop NMR has many advantages over similar analytical techniques due to its high degree of chemical specificity, especially when combining information from multiple chemical nuclei. Minimal or no sample preparation and quick data generation allows the deployment of benchtop NMR in QA/QC environments without the need for operation by R&D scientists. This saves significant time and money. One example is in the quality control of reaction feedstocks which are the raw chemical materials required to supply large-scale chemical manufacturing processes.

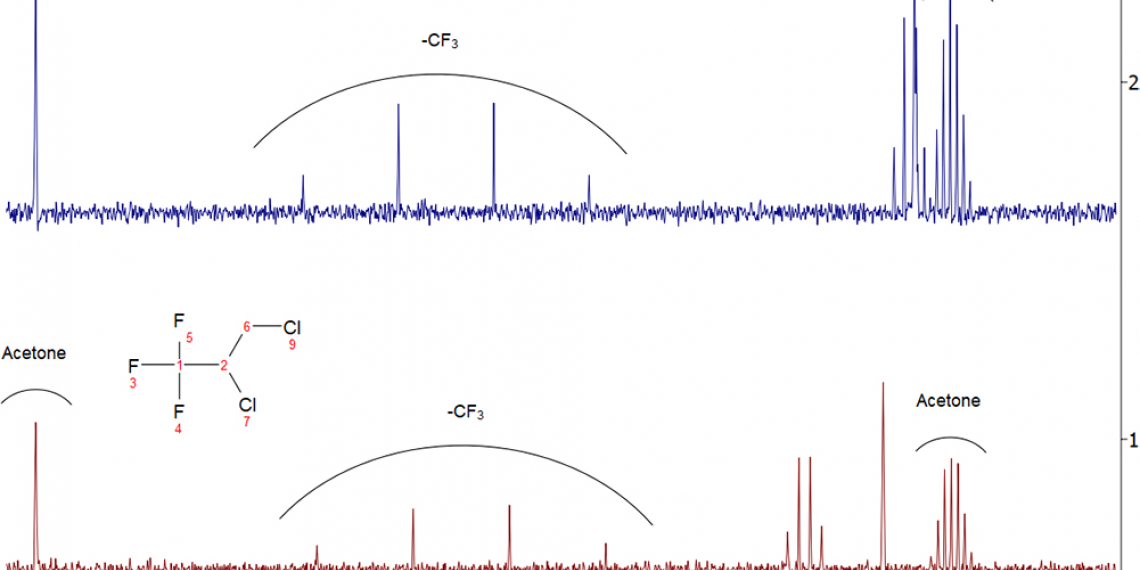

To confirm that lab technicians in a QA/QC environment, as well as organic, polymer and pharmaceutical chemists, can identify good or bad feedstock from a single, quick measurement, a specific industrial use case was investigated. A manufacturer of fluorochemical products sent us two samples from different suppliers. Both samples were reported to be the same reaction feedstock compound. One of the samples worked as a reaction feedstock but the second one did not. Could the samples be efficiently screened to identify the ineffective failed chemical? Importantly, was this failure due to degradation of the material, contamination, or was there another explanation?