Infrared spectroscopy of service oils, lubricants, and petroleum products can be challenging. With age and repeated thermal cycling, the oils become more viscous. Likewise, in some environments they may pick up particulates as they move through the parts of a system.

FT-IR of service oils is usually done in transmission mode because of its sensitivity to small chemical changes visible in the baseline of spectra. The traditional design of cell, where two windows are separated by a thin spacer and sandwiched between two backing plates, is not designed to be repeatedly taken apart and reset for cleaning and sample refilling. Thinner oils can be simply flushed through, but thicker oils cannot, making this a laborious and inconsistent sampling procedure.

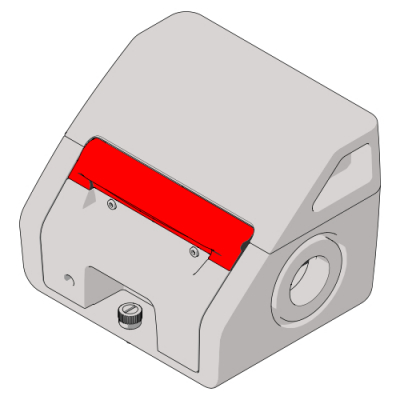

The Pearl™ solves these problems by permanently fixing the windows into matching Oyster™ holders, which assemble without tools to produce a fixed pathlength every time. The Oyster™ cell is mounted horizontally on a sliding drawer within the accessory. When the time comes to clean and refill the cell, the drawer is pulled out and the top Oyster™ window simply lifts out to give access to the windows for cleaning. When replaced, it resets to the same pathlength as before.

Oil analysis is now easier than ever thanks to the Pearl™.

Learn more about the Pearl™.