Image sensors usually consist of blue, green and red sensors alternating in a mosaic-like pattern. Intelligent software algorithms calculate a high-resolution colour image from the individual colour pixels. However, the principle has some inherent limitations: as each individual pixel can only absorb a small part of the light spectrum that hits it, a large part of the light is lost. In addition, the sensors have basically reached the limits of miniaturisation, and unwanted image disturbances can occur: colour moiré effects which have to be laboriously removed from the final image.

Researchers have been working for a number of years on the idea of stacking the three sensors instead of placing them next to each other. Of course, this requires that the sensors on top let through the light frequencies that they do not absorb to the sensors underneath. At the end of the 1990s, this type of sensor was successfully produced for the first time. It consisted of three stacked silicon layers, each of which absorbed only one colour.

This actually resulted in a commercially available image sensor. However, this was not successful commercially because the absorption spectra of the different layers were not distinct enough, so part of the green and red light was absorbed by the blue-sensitive layer. The colours therefore blurred and the light sensitivity was thus lower than for ordinary light sensors. In addition, the production of the absorbing silicon layers required a complex and expensive manufacturing process.

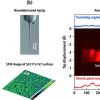

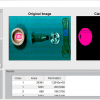

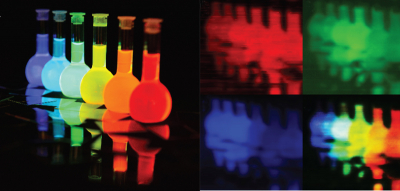

Researchers from EMPA have now succeeded in developing a sensor prototype that circumvents these problems. It consists of three different types of perovskites, and depending on their composition, they can, for example, absorb part of the light spectrum, but remain transparent for the rest of the spectrum. The researchers in Maksym Kovalenko’s group at EMPA and ETH Zurich used this principle to create a colour sensor with a size of just one pixel. The researchers were able to reproduce both simple one-dimensional and more realistic two-dimensional images with an extremely high colour fidelity.

The advantages of this new approach are clear: the absorption spectra are clearly differentiated and the colour recognition is thus much more precise than with silicon. In addition, the absorption coefficients, especially for the light components with higher wavelengths (green and red), are considerably higher in the perovskites than in silicon. As a result, the layers can be made significantly smaller, which in turn allows smaller pixel sizes. This is not crucial in the case of ordinary camera sensors; however, for other analysis technologies, such as spectroscopy, this could permit significantly higher spatial resolution. The perovskites can also be produced using a comparatively cheap process.

However, more work is still needed in order to further develop this prototype into a commercially usable image sensor. Key areas include the miniaturisation of pixels and the development of methods for producing an entire matrix of such pixels in one step. According to Kovalenko, this should be possible with existing technologies.

This work has been reported in two recent papers in NPG Asia Materials and Science.