Electronic circuits are miniaturised to such an extent that quantum mechanical effects become noticeable. Using photoelectron spectrometers, solid-state physicists and material developers can discover more about such electron-based processes. Fraunhofer researchers have developed a new spectrometer that works in the megahertz range.

Photoelectron spectroscopy opens a window on atoms together with their energy states and their electrons. In photoelectron spectroscopy, you shoot high-energy photons onto the surface of the solid-state object to be investigated: an electronic circuit, for instance. The high-energy light knocks electrons out of the atomic bond. Depending on what energy band they are in, they reach the detector at different times. Analysing the time it takes electrons to reach the detector, material developers can draw inferences about the energy states of the electron bands and the structure of the atomic bonds in the solid. All the electrons must start at the same time, which can be achieved only by using a pulsed laser beam. Usually the lasers work in the kilohertz range.

The problem is that if you set too many electrons free simultaneously with a pulse, they repel each other—making it impossible to measure them. The answer is turn down the power of the laser. However, to be able to measure enough electrons for a reliable sample, you need to arrange for suitably long measurement times. But sometimes this is not feasible, as the samples and beam source parameters cannot be kept sufficiently stable over such a long period.

Researchers at the Fraunhofer Institutes for Applied Optics and Precision Engineering IOF and for Laser Technology ILT have worked together with their peers from the Max Planck Institute of Quantum Optics to develop the world’s first photoelectron spectrometer that does not work in the kHz range, but at 18 MHz. This means that several thousand times more pulses strike the surface than with conventional spectrometers. This has a dramatic effect on measurement times. “Certain measurements used to take five hours; we can now complete them in ten seconds”, says Dr Oliver de Vries, scientist at Fraunhofer IOF.

The spectrometer consists of three main components: an ultrafast laser system, an enhancement resonator and a sample chamber with the actual spectrometer itself. As the initial laser, the researchers use a phase-stable titanium-sapphire laser. They change its laser beam in the first component: by means of pre-amplifiers and amplifiers, they increase the power from 300 µW to 110 W—a million-fold increase. In addition, they shorten the pulses. To do this, they use a trick whereby the laser beam is shot umpteen times through a solid, which widens the spectrum. If you then put these newly created frequency components of the pulse back together again—that is, if you combine all frequencies in a phase-correct manner—you shorten the pulse duration. “Although this method was already known beforehand, it was not possible until now to compress the pulse energy that we need here”, says Dr Peter Rußbüldt, group manager at Fraunhofer ILT.

The pulse duration of the laser light leaving the first component is already very short. However, the energy of its photons is not yet sufficient to knock electrons out of the solid. In the second component, the researchers therefore increase the photon energy and shorten the pulse duration of the laser beams once again in a resonator. Mirrors steer the laser light around in a circle several hundred times inside the resonator. Each time the light passes the starting point again, fresh laser radiation from the first component is superimposed onto it—and this is done in such a way that the power of the two beams is added together. Bottled up in the resonator, this radiation reaches such powerful intensities that high-energy attosecond XUV pulses are generated with many times the frequency of the laser beam.

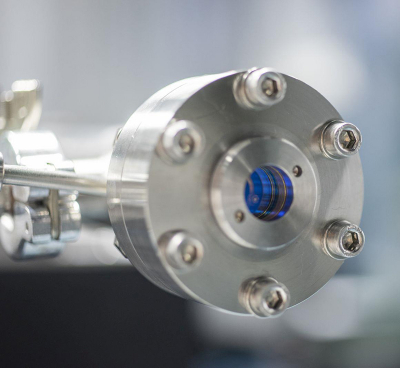

The researchers at Fraunhofer ILT use another trick to get the high-energy attosecond XUV pulses back out of the resonator. “We’ve developed a special mirror that not only withstands the high power, but also has a miniscule hole in the centre”, explains Rußbüldt. The bundle of high-harmonic rays, as the high-energy laser beams are called, generated by the process is smaller than the other waves that are circulating. While the lower-energy light beams continue to hit the mirror and be steered around in a circle, the high-energy bundle of rays is so thin and narrow that it slips through the hole in the centre of the mirror, exits the second component and is deflected into the sample compartment inside the third component.

The prototype of the photoelectron spectrometer has been completed and is located at the Max Planck Institute in Garching, where it is used for experiments and optimised with the collaboration of Fraunhofer researchers.