Articles and Columns

Claudia Paoletti

Program Manager, Transformation Unit - TS, European Food Safety Authority – EFSA, Via Carlo Magno 1/A, 43100 Parma, Italy

Philippe Davin

Sales Manager, Bulk Solids DPT, Iteca Socadei, Aix-en-Provence, France

Dominique François-Bongarçon

Agoratek International Consultants, Inc.

Introduction

The objective of this contribution is not to add to an already large list of horror examples of hidden economic losses, but rather to raise a cry of alarm about what is experienced as a classical denial of cost-consequential sampling recommendations. A couple of real-world examples borrowed from the mining industry will almost tell the story by themselves.

Oscar Dominguez

Global Principal Geoscientist QAQC, Resource Centre of Excellence, BHP

D. Aldwin Vogel

Technical & Quality Director, Commodities Global Service Lines, Bureau Veritas, Rotterdam, the Netherlands

Simon Dominy

Camborne School of Mines, Cornwall, UK and Novo Resources Corporation, Perth, Western Australia

Gold segregation in pulps

An underground narrow gold vein (1–2 m width) operation was known to contain coarse gold particles up to 1.2 mm in size, and rarely up to 4 mm. The vein had an average global reserve grade of 17 g/t Au. Monthly reconciliations were up to ±50 % on grade.

Chris Robben

SIX-S GmbH, Hinter der Kirche 1A, 22880 Wedel, Germany

This example originates from the mining industry with some parallels to the previous exploration example.

Quentin Dehaine

Senior Researcher at the Geological Survey of Finland (GTK), Circular Raw Material Hub (Vuorimiehentie 2) 02151, Espoo, Finland

Li Huachang and Zhu Mingwei

BGRIMM MTC Technology Co. Ltd, China

Martin Lischka

HERZOG Maschinenfabrik GmbH & Co. KG, Germany

Ralph Holmes

Honorary Fellow, CSIRO Mineral Resources, Australia

Case 1. Even a small sampling bias can have a BIG negative economic consequence

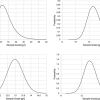

Poor sampling procedures for iron ore can lead to preferential exclusion of coarser high grade particles from shipment samples for analysis due to cutter apertures that are too small or cutter speeds that are too high. This leads to a negative bias on Fe content—the result is that shipments are also carrying away substantial lost revenues!

Pedro Carrasco, Pablo Carrasco and Eduardo Jara

Incorrect sampling operations cause huge economic losses to the mining industry, here illustrated by three industrial cases, which also show that when the Theory of Sampling (TOS) is applied correctly (ensuring unbiased sam-pling and analysis), considerable amounts of money can be saved.

Case 1

Sampling density influences the estimated value of mining plan alternatives

Kim H. Esbensen

Independent researcher, consultant, owner, KHE Consulting, Copenhagen

Abel Arkenbout

ToxicoWatch Foundation, Harlingen, The Netherlands

Geoff Lyman

Materials Sampling & Consulting. [email protected]

Elke Thisted

PhD, Manager Process Control & Development On-Line Analysis, Glencore Nikkelverk AS; Head of organisational committee for WCSB10

Pentti Minkkinen

Professor emeritus, Lappeenranta Lahti University of technology (LUT), Finland and President, Senior Consultant, Sirpeka Oy, Finland

Richard C.A. Minnitt

Visiting Emeritus Professor, University of the Witwatersrand, Johannesburg, South Africa

Kim H. Esbensen

KHE Consult

Money out the window—either way