Researchers at the National Institute of Standards and Technology (NIST) have come up with a way to shrink an electron spin resonance (ESR), usually used for bulk measurements of samples, down to a literally pinpoint-precision probe. The team’s ESR probe enables the analysis of very objects or specific spots on large ones. Their work is reported in a paper published titled “Electron spin resonance scanning probe spectroscopy for ultrasensitive biochemical studies” published in Analytical Chemistry.

The new probe is expected to have a broad range of applications in fields ranging from chemistry to semiconductor design and manufacturing.

“We are really over the moon about this work,” says NIST’s Jason Campbell. “Our new approach brings more than 20,000 times improvement in sensitivity over conventional ESR and allows for investigation of all sorts of samples that were never thought possible.”"

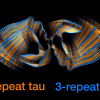

ESR is widely used in chemistry and biology research because it can reveal how molecules stick together. The wide range of applications spans anthropology, fuel science, physiology and meteorology. The expiration dates on some foods in the grocery store are determined using ESR as well. For many foods, shelf life can be predicted well by ESR monitoring the broken chemical bonds that occur over time.

But the technique’s sensitivity limits relegates it to analysing materials in bulk—often frustrating scientists, who have imagined wider uses for six decades. If ESR could be trained precisely on small objects or surfaces, it might detect defects on computer chip surfaces or tell us more about the workings of proteins on the surface of cells, to name just two possibilities.

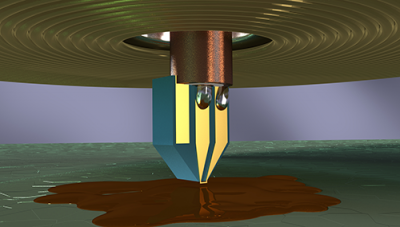

Its limitation stems from the need to place the sample into a small resonant chamber. ESR works by combining a magnetic field with microwave energy, to produce characteristic molecular bond vibrations. The resonant chamber focuses the microwaves on the sample.

“ESR is quick and convenient in some ways, but you don’t have as much control over the spot you’re exploring as you might like,” says NIST’s Jason Campbell. “And you can’t put anything metallic or conductive into the resonance chamber, meaning it’s very difficult to look at transistors or other electronic devices.”

The NIST team’s innovation was to forgo the resonant chamber entirely. Instead, they introduce microwave energy by forcing high-frequency current through a microscopic wire, which acts as a tooth-like probe tip that can be moved within a few micrometres of a sample material. Using this approach, the team was able to examine specific points on a surface.

“Combined with other techniques, we can imagine seeing atom-sized defects in chips,” says Campbell, an electrical engineer whose work often concerns the semiconductor industry. “But we’re also excited for the huge number of people who can now use this technique in chemistry and biology. It’s a simple, elegant solution to a longstanding problem.”