Imaging spectrometers record a series of monochromatic images that are used for both spatial and spectral analysis of an area. This analytical approach is widely applied in fields such as atmospheric science, ecology, geology, agriculture and forestry. However, the large size of the instruments has prevented it from being used in some applications.

In Applied Optics, researchers led by Ronald Lockwood from MIT Lincoln Laboratory describe their new Chrisp compact VNIR/SWIR imaging spectrometer (CCVIS). It has a volume about >10× smaller than most of today’s devices. One version of the CCVIS is 8.3 cm in diameter and 7 cm long, about the size of a drinks can. The spectrometer is designed to record spectral images over a wavelength range of 400–2500 nm.

“Our compact instrument facilitates the application of imaging spectroscopy for a variety of scientific and commercial problems, such as deployment on small satellites for planetary exploration or using unmanned aerial systems for agricultural purposes”, said Lockwood. “We believe that our new spectrometer could also be used to study climate change, one of the most exciting applications of an imaging spectrometer.”

Most of today’s imaging spectrometers use an Offner–Chrisp optical configuration because it offers excellent control of optical errors called aberrations. However, this design requires a relatively large optical setup. The new CCVIS developed by the researchers performs much like the Offner–Chrisp configuration but with new optical components that create a more compact design.

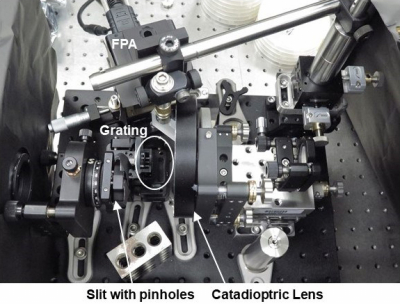

To make the new CCVIS, the researchers used a catadioptric lens that combines reflective and refractive elements into one component. This created a more compact instrument while still controlling optical aberrations. The researchers also used a special flat reflection grating that is immersed in a refractive medium rather than in air. This grating takes up less space than a traditional grating while maintaining the same resolution.

“The CCVIS uses a flat grating rather than a concave or convex grating that requires manufacturing with complex electron-beam lithography or diamond machining techniques”, said Lockwood. “We developed a grayscale photolithographic microfabrication approach that uses a one-time exposure to make the grating and doesn’t require labour intensive electron-beam processing.”

To test their new design, the researchers demonstrated the spectrometer using a laboratory setup. Their experiments verified that the CCVIS had the expected performance over the full field of view.

“The CCVIS’s compact size means that it can be made into modules that could be stacked to increase the field of view”, said Lockwood. “It also makes it relatively easy to keep stable with no temperature changes so that optical alignment, and thus spectral performance, remains unchanged.”

As a step toward the ultimate goal of a space-based demonstration, the researchers are seeking funding to develop a full prototype that could be thoroughly tested from an airborne vehicle.