Zheng-Zhu Zhang,a Sheng-Peng Wang,a Xiao-Chun Wana and Shou-He Yan*,b

aKey Laboratory of Tea Biochemistry & Biotechnology, Ministry of Education and Ministry of Agriculture, Anhui Agricultural University, Hefei 230036, China

bInstitut des Sciences de la Vie, Université de Louvain, Croix du Sud 2/8, 1348 Louvain-le-Neuve, Belgium. E-mail: [email protected]

Introduction

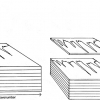

Tea is an agricultural product produced from the raw material of young shoots of the plant Camellia sinensis L, which is native to China. It is harvested for processing from the bud, the first leaf and the first three leaves up to a maximum of four leaves; see Figure 1. Sensory testers classify the tea for its tenderness according to the position order from the bud to the leaves used. The youngest part, which is the bud, usually has a fresh weight of about 30 mg to 50 mg with, generally, about 75% moisture content; so it is easy to understand that if only the buds were used, this would produce a very low quantity, but it would be the best quality tea.

In tea manufacturing, the raw material includes the bud with the first one, two or three leaves; its quality will depend on a mix of the quality and quantity of the selected leaves, namely, according to the types of tenderness: the best (bud + first leaf), good (bud + first two leaves) and middle (bud + first three leaves); acceptable is bud + first four leaves. The highest quality is the best tenderness class (100% bud + first leaf), which is called class 1. Each tea type has different quality class ranges, with a maximum of six classes represented here by the proportions (%) of three tenderness types shown in Table 1.1

Table 1. The variable quality of the raw material from class 1 to 6 of tea shown by the proportions (%) of three tenderness types of tea samples.

Tenderness types | Class 1 | Class 2 | Class 3 | Class 4 | Class 5 | Class 6 |

Bud + 1st leaf | 100 | 85 | 75 | 25 | 0 | 0 |

Bud + 1st two leaves | 0 | 15 | 25 | 75 | 75 | 20 |

Bud + 1st three leaves | 0 | 0 | 0 | 0 | 25 | 80 |

From a biochemical point of view, scientists believe that the bud and each leaf are independent variables, thus tea quality must be evaluated with the position of each leaf considered separately. When a new bud is formed, the old bud becomes the first leaf and the others following the position order then become second leaf and third leaf etc. Metabolic activity changes occur according to the position of the leaves; this has, in turn, a direct influence on the quality of the tea. Thus, sensory and composition properties depend on small molecules such as amino acids, caffeine and soluble nitrogen. The higher these contents are, the better the tea quality. Conversely, a content of larger molecular components such as lignin and protein is always a characteristic of old leaves and, hence, inferior quality tea.2

The quality of tea may be assessed according to both points of view, i.e. first, according to an independent variable, namely bud and leaves studied separately and second, according to a mixed variable, namely in the used raw material in which buds are mixed with one, two or three leaves. What is the difference between these? Is one better than the other?

The aims of the studies discussed in this article are not only to find an answer to the above two questions and to understand both the composition and sensory properties of tea, but also to compare and judge both points of view by using partial least squares (PLS) techniques of near infrared (NIR) spectroscopic data recorded from various tea samples. However, developing a NIR online method to evaluate the quality of fresh tea needs a solid scientific base.

Materials and methods

Materials

All fresh tea leaf samples studied were picked from the tea garden of Anhui Agricultural University, Hefei, Anhui, China, between 15 April and 30 April 2008. There were three types of fresh tea leaves: (1) four varieties were picked from the bud to the first, second, third and fourth leaves separately; each position from each variety was represented by 10 to 20 examples and analysed in order to get the data shown in Figures 2 and 3; (2) 78 leaf position samples (without buds), which included the first, second, third and fourth leaves separately, were analysed, see Table 2; (3) 84 raw material tea samples with four tenderness types ranging from bud + first leaf to bud + two, three or four leaves, respectively, were analysed, see Table 3.

Table 2. Three main component compositions (see Figure 3) and quality index values for the bud and leaf positions. The values shown in brackets are calculated as variations of relative % from the bud or the first leaf as 100% separately.

Components | Quality evaluation from position of tea leaf (n = 78 + 4†) | ||||

Bud* | First leaf | Second leaf | Third leaf | Fourth leaf | |

Mean (FW %) | 74.81 | 72.31 | 72.09 | 70.84 | 69.10 |

Mean (DW %) | 5.10 | 4.72 | 4.05 | 3.44 | 3.10 |

Mean (DW %) | 5.25 | 7.26 | 9.22 | 10.58 | 11.78 |

Mean | 0.72 | 0.42 | 0.32 | 0.23 | 0.18 |

†buds data comes from an analysis of samples from four varieties, see Figure 2.

Table 3. Evaluation of three main component properties; quality indexes (QI) are set according to the tenderness types of raw material samples from the manufacturer’s point of view. The values shown in brackets are calculated as variations of relative % from the bud + first leaf as 100%.

Components | Quality evaluation by four type tenderness raw material (n = 84) | |||

Bud + first leaf | Bud + first two leaves | Bud + first three leaves | Bud + first four leaves | |

Mean (FW %) | 73.32 | 74.47 | 74.48 | 73.31 |

Mean (DW %) | 4.89 | 4.33 | 3.65 | 3.39 |

Mean (DW %) | 6.67 | 8.15 | 9.99 | 11.67 |

Mean | 0.53 | 0.40 | 0.27 | 0.21 |

Experimental

Weight contents

(1) The fresh mean weight of four variety control samples from bud to the first, second, third and fourth leaves were calculated for each position (Figure 2); (2) all moisture contents of the samples were calculated as fresh weight (FW) %. Chemical compound analysis was undertaken as: (1) total nitrogen content was determined according to the Kjeldahl method;3 (2) amino acids content was determined by the ninhydrine method and caffeine was determined by a UV spectrophotometric method;2 (3) the lignin content was determined according to the general method;4 and (4) sample quality indexes (QI) were calculated using the formula: moisture × total nitrogen/lignin.5,6

NIR spectroscopy

The diffuse reflectance spectra log10 (1/R) of tea samples were recorded over the range 12,500–4000 cm–1 using a Bruker MPA Fourier transform (FT) NIR spectrometer (Bruker Optik GmbH, Ettlingen, Germany). About 60 g of fresh tea leaf samples (except bud samples) were put into a sample cup (97 mm diameter). Thirty-two scans for each spectrum and each sample were collected three times and then an average was established; the data interval of each spectrum was 3.68 cm–1, thus each spectrum contained 2307 data points.

Software

All data analysis methods were performed using the Bruker OPUS 6.5 software package (Bruker Optik GmbH, Ettlingen, Germany).

Results and discussion

The characteristics of young shoots: sensory properties

The leaf position order in the young shoots has also been called tea age or tea tenderness by sensory testers. There are two main characteristics: the first is that young shoots grow rapidly: the mean weight values increased from bud (30–50 mg) to the first leaf (80–120 mg), second leaf (180–250 mg), third leaf (260–350 mg) and fourth leaf (370–450 mg), respectively; see Figure 2.

The second characteristic is that the highest metabolic activity exists within the young shoots. There is a higher quantity of smaller molecular components in the youngest leaves, which contain more than 70% (FW) of moisture, a rapid decrease in the relative content of small molecular compounds such as amino acids, caffeine and soluble nitrogen components and a rapid increase in the relative content of larger molecular comports such as lignin (see Figure 3) accompanying leaf age. According to the most widespread point of view in biochemistry, the small molecular components are constituents and precursors of the larger ones, so polyphenols such as hydrolysable tannins and other phenolic components are believed to be important precursors of lignin,7 while amino acids and caffeine are believed to be important precursors of protein and nucleic acids.8

Figure 3 shows that amino acids, caffeine, soluble nitrogen and lignin contents vary systematically and separately following tenderness: from the position of the leaves, from bud (0) through the four leaf positions.

Younger shoots all contain higher moisture content, which is an important sensorial and composition property, because the higher moisture contents assure the highest metabolic activity; the latter yields the global characteristics of smell, flavour and taste. This fact is accepted not only by scientists and sensory testers but also by the tea manufacturers.

Tea quality evaluation by using composition properties

According to Zhang et al.5 and Wang et al.,6 the moisture, total nitrogen and lignin contents are the three principal composition properties; they were the first to propose establishing the formula of a QI (quality index) = (moisture × total nitrogen)/lignin. Their reports are confirmed from a scientific standpoint in Table 2, which shows that the QI values decrease very rapidly from the bud at 0.72 to 0.42 for the first leaf to being only 0.18 in the fourth leaf.

The data in Table 3 show the values from a tea producer’s viewpoint: it shows the values determined from the 84 raw material samples of fresh tea leaves according to their four tenderness types: No significant difference is observed between their moisture contents; nitrogen levels decrease from about 4.9% to 3.4%; whereas, the lignin content increases from ca 6.7% to ca 11.7%.

Table 2 and Table 3 enable us to compare both points of view—that of the scientists and that of the tea manufacturers. The scientists believe that the changes in metabolic activity occur according to the position of the leaves, while the manufacturer’s focus is, clearly, on the stability and productivity of the tea quality. The values in Table 2 show that nitrogen decreases from the bud relative value of 100% to 34% for the fourth leaf, but that lignin increases from the bud relative value of 100% to 224% for the fourth leaf. However, since the bud is not generally used independently as a raw material by the manufacturers, they assess raw material tenderness as depicted in Table 2, in which we observe the nitrogen content decreases from “100%” (first leaf) to 66% (fourth leaf), while lignin content increases from a value of 127% (second leaf) to 162% (fourth leaf). From this comparative analysis, we can see that, while the trends are similar, the relative changes are less between the leaves from extreme positions than those between the bud and the forth leaf; however, despite these value differences, both the scientist’s and manufacturer’s standpoints are similarly met and the trends in agreement.

It is very interesting to note from Table 2 and Table 3 that: the QI value decreases from “100%” (first leaf) to 43% (fourth leaf), see Table 2 and similarly decreases from “100%” (bud + first leaf) to 40%, see Table 3. So, one observes nearly the same % QI decrease from both sets of data. Therefore, we might say that the scientists’ and the manufacturers’ assessment viewpoints of tea quality are nearly equally met!

Estimation of tea quality by PLS techniques

In the research presented here, we have paid special attention to fresh tea leaves, thus all samples contained more than 70% to 75% moisture. We have studied the relationships between moisture, nitrogen and lignin properties as QI values according to both points of view discussed above using NIR spectroscopy with PLS data analysis. The NIR spectra of 84 raw materials are presented in Figure 4.

PLS regression analysis was used to estimate, from the NIR spectroscopic data, comparison calibration and prediction models from both the scientist’s and manufacture’s viewpoint, as shown in Table 4 and Table 5, respectively.

Table 4. Estimation of three main composition properties and QI values of the 78 leaf position samples by NIR spectroscopy PLS analysis for calibration and prediction models

Leaf position models | Pre-processing† | PLS factors | Calibration (n = 45) | Prediction (n = 33) | ||

R | RMSECV | r | RMSEP | |||

Moisture | 1DOD + MSC | 7 | 0.97 | 0.453 | 0.94 | 0.518 |

Nitrogen | MSC | 7 | 0.88 | 0.298 | 0.87 | 0.313 |

Lignin | 2DOD | 5 | 0.96 | 0.415 | 0.94 | 0.443 |

QI | 1DOD | 4 | 0.92 | 0.040 | 0.89 | 0.047 |

†Data pre-processing:

1DOD or 2DOD are the first or the second derivative of an original spectrum, respectively.

MSC, multiplicative scatter correction;

R, coefficient correlation for the calibration set; r, coefficient correlation for the prediction set.

RMSECV, root mean-square error of cross-validation for the calibration data set.

RMSEP, root mean-square error of cross-validation for the prediction data set.

Table 5. Estimation of three main composition properties and QI values of 84 raw material samples by NIR spectroscopy PLS analysis for calibration and prediction sets.

Raw material models | Pre-processing | PLS factors | Calibration (n = 46) | Prediction (n = 38) | ||

R | RMSECV | r | RMSEP | |||

Moisture | 1DOD + MSC | 7 | 0.93 | 0.424 | 0.90 | 0.466 |

Nitrogen | 1DOD + MSC | 7 | 0.82 | 0.394 | 0.81 | 0.412 |

Lignin | 2DOD | 6 | 0.93 | 0.684 | 0.90 | 0.712 |

QI | 1DOD | 7 | 0.90 | 0.053 | 0.88 | 0.058 |

When comparing both correlation coefficients (R and r), it can be seen that those in Table 4 are a little higher than those in Table 5. Naturally, the RMSECV and RMSEP moisture, nitrogen and lignin values are different in both tables. However, with the same 1DOD pre-processing for the QI analysis by PLS, the R values between the calibration and prediction sets for both sets of data show no significant differences. Through NIR spectroscopy PLS data analysis evaluation it is very easy, therefore, to appreciate that the viewpoints of scientists and manufacturers are close and that the technique could be used as an evaluation tool.

Conclusions

From the analysis of both approaches we can conclude that both points of view are mutually supportive. The approach of constituting raw material out of a mix of bud and leaf in variable samples is more appropriate to tea manufacturers. NIR spectroscopy PLS techniques are useful for an evaluation of sensory and composition properties of young tea shoots, and can also estimate tea quality. A NIR spectroscopy-based tea quality online evaluation method used in the production process would considerably accelerate the assessment and subsequent classification of the raw material.

References

- Z.Z. Zhang, W.G. Wu and X.C. Wan, Rules of Huang Shan Mao Feng tea production process, DB34/T871. Control Food Quality Office, Anhi, China (2008).

- S.H. Yan, “Evaluation of the composition and sensory properties of tea using NIR spectroscopy and principal component analysis”, J. Near Infrared Spectrosc. 13, 313–325 (2005).https://doi.org/10.1255/jnirs.562

- Y. Pomeranz and C.E. Meloan, Food Analysis: Theory and Practice, Third Edition. Chapman & Hall, London, UK, pp. 737–743 (1994).

- M. Smiechowska and D. Pizemvslaw, “Crude fiber as a parameter in the quality evaluation of tea”, Food Chem. 94, 366–368 (2006).https://doi.org/10.1016/j.foodchem.2004.11.026

- Z.Z. Zhang, B.Y. Liao, S.H. Yan and X.C. Wan, “Application prospect of near infrared spectroscopic techniques on the fidelity evaluation of tea quality”, Shipin Gongye Keji 30(9), 349–352 (2009).

- S.P. Wang, X.C. Wan, M.X. Lin and Z.Z. Zhang, “Estimation the quality of tea leaf materials based on contents of moisture, total nitrogen and crude fiber by NIR-PLS techniques”, J. Tea Sci. 31(1), 67–71 (2011).

- T. Stevanovic, P.N. Diouf and M.E. Garcia-Perez, “Bioactive polyphenols from healthy diets and forest biomass”, Curr. Nutr. Food Sci. 5(4), 264–295 (2009).https://doi.org/10.2174/157340109790218067

- E. Ito and H. Ashihara, “Contribution of purine nucleotide biosynthesis de novo to the formation of caffeine in young tea (Camellia sinensis) leaves”, J. Plant Physiol. 154(2), 145–1 51 (1999).

Editor note

The interested reader may wish to also refer to an article by the same author: