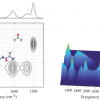

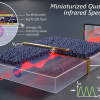

Using laboratory-grade equipment with 3D printable optical setups, the research group of Professor Masahide Takahashi of the OPU Graduate School of Engineering at Osaka Prefecture University has established an easy, versatile, yet highly sensitive approach to identify the orientation of molecules and chemical bonds in crystalline organic–inorganic hybrid thin films deposited on a substrate as small as 10 nm, “even film with three molecular layers”. They used an FT-IR spectrometer and polarised IR light with their own designed 3D-printed attenuated total reflectance (ATR) unit. FT-IR spectrometers have not been able to reveal the three-dimensional orientation of these molecules relative to the substrates. This is important to the manufacturing of thin-film devices that can be nanometres in size, as an unpredicted shift in molecular orientation at that level can cause the entire structure of the device to break down.

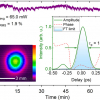

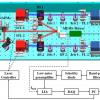

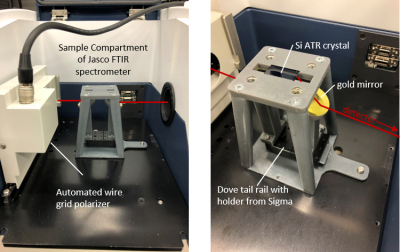

“We realised that by re-orienting the sample, we could introduce polarised light directly into the substrate of the thin film, generating an evanescent wave that heats up the sample, exciting certain molecules and betraying their orientation”, states Bettina Baumgartner, a visiting researcher on the team, “we just needed a new kind of sample interface”, adds Associate Professor Kenji Okada. This is where the team designed a brand-new ATR optical setup that bounces polarised infrared light through the entirety of the sample substrate allowing the team to observe the vibration of all molecules aligned with the electric field component of the infrared light, revealing their orientation. Any lab with a 3-D printer can make these ATR optical setups.

This method, which the team used to obtain the structural information of metal–organic framework thin film with a degree of crystal orientation comparable to X-ray structural analysis, is expected to be a useful method in many situations in materials science, such as where orientation control is linked to controlling physical properties, the functional improvement of porous materials used for CO2 capture and the development of new heterogeneous catalysts.