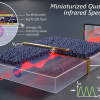

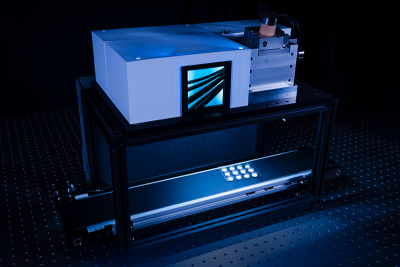

With an inline-capable, laser-based infrared spectroscopy measurement system, researchers at the Fraunhofer Institute for Applied Solid State Physics IAF want to support industrial companies from the pharmaceutical, chemical and food industry in making quality assurance measurements and process control more reliable and at the same time more efficient. The system has a flexible design and a high spectral scanning speed that allows it to be integrated into existing visual inspection systems, enabling full spectroscopic inspection.

“The measurement system vividly demonstrates the great benefit of laser-based infrared spectroscopy for industrial sectors in which products have to be verified or differentiated reliably and quickly”, emphasises Dr Marko Härtelt, responsible project manager at Fraunhofer IAF.

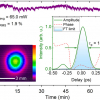

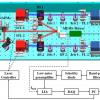

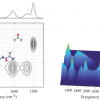

The specific advantages of the system result from the backscattering spectroscopy method in the mid-infrared with wavelengths in the range of 4–12 μm. Since molecular compounds have very characteristic absorption and emission lines in this spectral range, they can be clearly identified. One of the core components of the measurement system is a broad-emitting and spectrally fast-scanning laser module. It combines quantum cascade lasers (QCLs) from Fraunhofer IAF and micro-opto-electro-mechanical grating scanners (MOEMS) from the Fraunhofer Institute for Photonic Microsystems IPMS. The high brilliance of the light source and the unique properties of the MOEMS scanner enable infrared spectroscopy at a rate of one kilohertz.

A neural network analyses measurement results, and enables the system to drastically minimise the error rate and at the same time the required measurement time.