Readers may remember a news story from March 2021 about taking inspiration for a hyperspectral imaging sensor from the eyes of the mantis shrimp. Now another group has developed a miniature NIR sensor, again taking inspiration from the colourful shrimp.

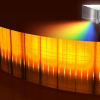

While the human eye is impressive, it’s far from being the most advanced natural light sensor out there. “The eyes of the Mantis shrimp have 16 different types of cells, which are sensitive to ultraviolet light, visible and near infrared (NIR) light”, says Kaylee Hakkel, a PhD researcher in the Photonics and Semiconductor Nanophysics group at Eindhoven University of Technology. “And measuring the spectrum in the infrared is most interesting for applications in industry and agriculture, but there’s one major issue—current near infrared spectrometers are just too big and expensive.”

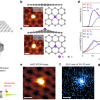

Hakkel and her collaborators have solved this issue by developing a NIR sensor that fits onto a small chip. And just like the eye of the Mantis shrimp, it has 16 different sensors—but they are all sensitive in the NIR. “Miniaturisation of the sensors while keeping costs low was a major challenge. So, we designed a new wafer-scale fabrication process to achieve this. It’s low-cost because we can produce multiple sensors at the same time, and it’s ready, right now, for use in practical applications in the real world”, Hakkel adds. “The sensor chip is small and could even be embedded in future smartphones.”

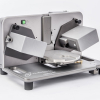

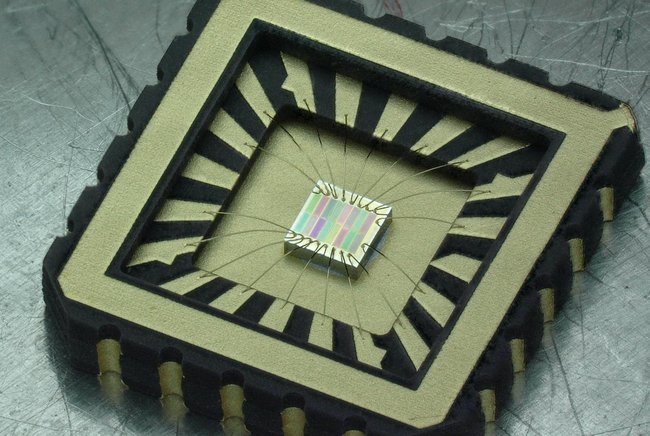

The ChipSense chip. Courtesy Eindhoven University of Technology.

Andrea Fiore, research lead from the Department of Applied Physics and the Eindhoven Hendrik Casimir Institute, is delighted with their research team’s work. “We’ve been investigating this technology for a number of years. And now we’ve successfully integrated the spectral sensors on a chip, while also dealing with another key issue—efficient use of the data”

Normally, when a sensor measures light, the generated signal is used to reconstruct the optical spectrum for the material. Sensing algorithms are then used to analyse the data. In this new approach, the researchers show that the step of spectral reconstruction isn’t needed. In other words, the signals generated by the sensors can be sent straight to the analysis algorithms. “This significantly simplifies the design requirements for the device”, notes Fiore.

With the sensor in hand, the researchers then tested the sensor in a number of experiments, as explained by Maurangelo Petruzzella, who also works at the startup company MantiSpectra. “We used the sensor to measure the nutritional properties of many materials including milk. Our sensor provided comparable accuracy in the prediction of fat content in milk as conventional spectrometers. And then we used the sensor to classify different types of plastic.”

“Besides these applications, we anticipate that the sensor could be used for personalised health care, precision agriculture (monitoring the ripeness of fruit and vegetable for instance), process control and lab-on-chip testing. We now have a full development kit available based on this technology, the SpectraPod™, that companies and research institutes are using to build their applications. And the great thing is that this sensor could even be commonplace in the smartphones of the future meaning that people could use it at home to check the quality of their food or check aspects of their health”, adds Petruzzella.

After defending her PhD, Hakkel will be joining Petruzzella at the startup MantiSpectra where they will develop the sensor for more practical applications. “I’m really excited to start working on the next phase of the sensor development with MantiSpectra. This sensor could contribute to a cleaner environment and address food waste, applications that are important for everyone.”